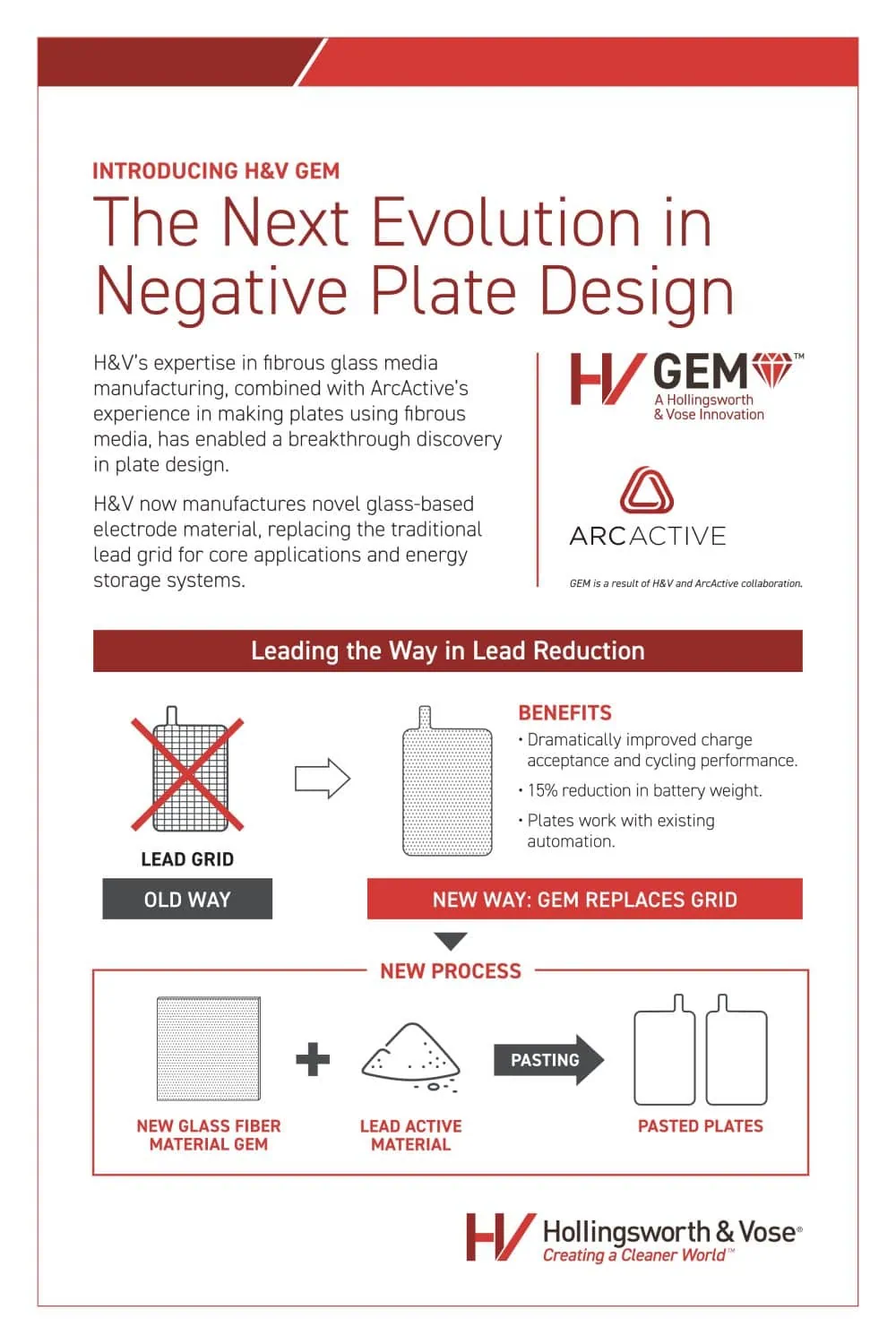

Hollingsworth & Vose (H&V) has pioneered GEM, a nonwoven glass substrate that, when infiltrated with battery active material, represents a breakthrough discovery in plate technology for the lead acid battery industry. This glass electrode material could open up new markets and industries due to its enhanced performance, and we are currently working with industry partners to explore the possibilities of this exciting innovation.

Read on to learn more about GEM’s potential value to lead acid batteries as a negative plate alternative, including its performance summary and prospective applications.

GEM as a Lead Acid Battery Plate Alternative

As an alternative to traditional lead acid battery plates, GEM offers distinct benefits in the following key areas:

- Performance. In a lead battery, there are several failure mechanisms directly associated with the negative lead plate itself. Replacing the lead grid with GEM eliminates many of these negative plate failure mechanisms as well as extends the health of the positive plate, which ultimately translates to significant improvement in charge acceptance and cycle life performance.

- Manufacturability. The lead battery manufacturing relies on grid making and lead active mass pasting equipment. Engineering firms that produce equipment for this industry can replace or modify it with those suited for glass electrode rolled good materials. Once integrated into the new plate manufacturing equipment, GEM can drastically simplify lead acid battery manufacturing. This is very appealing to major battery companies and engineering firms in the long run, as easier manufacturability combined with improved performance opens up a broader range of market opportunities.

Leveraging Existing Supply Chain

To the battery manufacturer accustomed to working with absorbent glass mat (AGM) separators from H&V, the supply chain remains the same. H&V production of GEM requires no new raw materials; therefore, leachate and quality concerns are eliminated.

Pore Structure

At H&V, our extensive fiber base and wetlaid knowledge allow us to produce GEM with optimal pore sizes to offer three-dimensional support for active mass. GEM is microfiber-based, but it is very different from AGM battery separators. GEM has a more “open” pore structure compared to AGM to enable active mass penetration. As a result, the active paste material can be contained wholly within GEM’s fibrous pore structure that, when dried and cured, has handling similar to traditional negative plates. The plates have shown to work well with all downstream robotics for plate handling.

GEM Applications

Potential applications of GEM technology in lead acid batteries include:

- Automotive. GEM can achieve sustained, up to 4X higher dynamic charge acceptance (DCA) with low water loss. It supports high charge recoverability for electric and hybrid vehicles and is a cost-effective way for customers to comply with low-CO2 emissions regulations. GEM also reduces the chances of an auxiliary battery having an insufficient state-of-function (SoF) and rendering the vehicle inoperable.

- Motive Power (Forklift) & Deep Cycle batteries. GEM containing batteries can be charged rapidly, leading to shorter charging time and more duty from the batteries between charges. In addition, a better State of Health (SoH) for batteries can be maintained in these applications.

- UPS AGM Battery. When used in AGM batteries, GEM can potentially prolong the time it takes for the separator to dry out, reducing dryout warranty claims.

GEM Performance Summary

H&V has performed extensive electrical testing on GEM in an automotive prismatic two-volt cell battery. Here are the key findings:

- 2-4x start-stop dynamic charge acceptance for hybrid EVs and charge recovery for auxiliary battery in electrical vehicles

- GEM provides very low water consumption in testing

- GEM exhibits the required strength for relevant commercial processing

- GEM plates can be effectively handled by robots in manufacturing

- GEM exhibits equivalent cold cranking voltage

Learn More About GEM From H&V

With generations of industry experience, Hollingsworth & Vose has the knowledge and resources to provide our clients with innovative energy solutions and filtration solutions that make the world a cleaner and more sustainable place. As a trusted global leader in developing battery separators, we are committed to ongoing research and development into GEM technology. With advanced manufacturing and engineering capabilities, H&V is creating new solutions that will shape the future of existing and emerging battery technologies.

Contact us today to learn more about GEM or our other advanced material solutions.