Microfiltration vs. Ultrafiltration: What’s the Difference?

Leave a CommentMicrofiltration and ultrafiltration are separation methods that rely on filter media with tiny pores to remove solids from a liquid stream. Factors such as the pore size and contaminants present affect the degree of purification.

Microfiltration and ultrafiltration strip solids from liquid streams until they are sent to more intensive treatment processes in a variety of industrial applications. This is required to purify streams for the production of potable water, to handle waste to meet effluent regulations, and to perform a variety of other separation processes.

Microfiltration and ultrafiltration membranes come in various material options and configurations to meet the needs of the intended application.

What Is Microfiltration?

Microfiltration is a filtration and separation process that uses porous filter media, often pleated into a cartridge format, to filter particles between 0.1 and 10 micrometers. Microfiltration allows for cleaner water and cleaner processes by relying on physical separation, reducing the need for chemical treatments.

In industrial applications, microfiltration is an ideal method of removing larger solids prior to other separation methods, including ultrafiltration and reverse osmosis. Various applications rely on microfiltration filter media to remove bacteria and small pollutants.

Industrial process streams typically integrate microfiltration in the following treatment applications:

- Food & beverage processes

- Wastewater treatment

- Bioprocesses

- Ink & dye production

- Oil separation from water

- Dairy processing where protein molecules are permitted

- Pharmaceuticals

Microfiltration is a suitable pre-treatment for streams prior to ultrafiltration. It improves the efficiency of the ultrafiltration filter media by removing large solids.

What Is Ultrafiltration?

Ultrafiltration, like microfiltration, separates solids from a pressurized liquid stream using membranes of tiny pores. An ultrafiltration membrane’s pores are around 0.01 micron in dimension. An ultrafiltration membrane can isolate the same solids from a liquid stream as microfiltration filter media, but with the right level of strain, it can also separate viruses.

Various industrial process streams and commercial treatment applications rely on ultrafiltration, including:

- Beverage clarification processes

- Removal of pathogens from milk

- Separating oil from water

- Chemical separation processes

- Protein concentration

- Wastewater treatment

If your application relies on microfiltration before ultrafiltration, Trupor® microfiltration filters provide optimum reliability and efficiency.

Check out the dedicated Trupor® site for more information:

Microfiltration with Trupor®

Microfiltration is a preferred liquid purification solution that various industries use to process liquid streams. Trupor® is a reliable and high-performance filtration solution for microfiltration, using the leading technology in microporous filtration media. You can rely on Trupor® to deliver best-in-class flow rates and remarkable reliability.

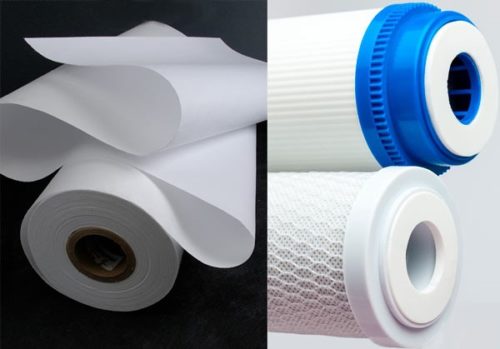

Trupor® is a patented filtration technology from Hollingsworth & Vose. It is sold as a rolled good with a composite structure and superior pore size uniformity. Our microfiltration filter media delivers performance stability, meeting the thinnest efficiency levels possible. They also have a long lifespan and can help you save time and money in a range of filtration applications.

The Importance of Microfiltration Membranes in Water Treatment

Leave a CommentWater cleanliness and filtration standards are rising in many parts of the world. That means municipal water treatment facilities and commercial water purification systems need to be increasingly advanced to keep up. One of the most important tools in an advanced filtration system is a microfiltration membrane.

Microfiltration membranes use physical separation processes to remove contaminant particles, reducing the need for chemical treatments. Although there are many types of filtration processes that incorporate membranes, one of the most preferred processes is pressure-driven membrane filtration, which forces liquids through a large membrane at high pressure levels.

There are four subtypes of pressure-driven membrane filtration, each of which handles particles of various sizes. These processes include:

- Reverse osmosis

- Nanofiltration

- Ultrafiltration

- Microfiltration

Microfiltration Membrane Uses

Microfiltration processes feature membranes that can block particles as small as 0.1 microns. This makes microfiltration an important first step to complex and high-purity filtration systems. By removing larger contaminants like bacteria and suspended solids, microfiltration prepares fluid streams for further treatment processes.

Microfiltration membranes are commonly used in the following applications:

- Boiler refeeds

- Clarifying and sterilizing water for beverage, food, and pharmaceutical industries

- Cooling towers

- Providing desalination pretreatments in multi-stage processes

- Potable water treatment

- Safer water discharge processes

- To optimize water re-use filtration systems in industrial and municipal settings

- Treating water at point-of-use (POU) and point-of-entry (POE) ports

- Water reuse

- Wastewater treatment

Microfiltration systems can be used in a diverse range of applications. Because of this, there are many membrane options to choose from to achieve the intended level of filtration. It’s important to carefully consider the level of water contamination, the housing construction and geometry of the water treatment system, the membrane material, the volume of treated water, and more when selecting the proper microfiltration membrane.

As municipalities and industrial users pursue new standards and approaches to waste water treatment, Trupor® enables new approaches to water re-use. Learn more here.

Check out the dedicated Trupor® site for more information:

Microfiltration Membrane From Hollingsworth & Vose

At Hollingsworth & Vose, we specialize in designing and manufacturing innovative industrial solutions for filtration processes. We create products for a wide range of industries, and our microfiltration membrane solutions allow facilities to efficiently manage and treat water. If you want to learn more about our microfiltration products and how they can optimize your facility’s processes, we recommend our patented Trupor® product.

This unique microporous filtration media is sold as a rolled good and provides best-in-class flow rates for efficient water processing. It can be used in dead-end and cross-flow applications to streamline reliable water treatment. Because of its reliability and improved flow rate, industries can optimize their water treatment systems for time and cost savings without compromising the integrity of their water purity. Other benefits of our Trupor® microporous filtration product include:

- Excellent composite structure that extends the product lifespan

- Uniform pore sizes for consistent performance

- Stable performance in the thinnest possible efficiency layer

- Ability to filter novel fluid streams because of its superior flow rate

Our Trupor® microfilters are available in nylon and PES/PBT varieties. They can be used as a co-pleated capacity layer to extend the life of your system and reduce change-outs or as an efficiency layer for improved flow. Contact us today to learn more about our microfiltration water treatment solutions.